News

Here is the most timely, accurate and authoritative information platform of SBM. We are based on our own development, whether it is the SBM's hot spots or technological innovation, we will present for you in the first time...

Manganese ores are widely distributed in nature,almost all kinds of ores and silicate rocks contain manganese. Manganese ores are mainly divided into manganese oxide and manganese carbonate, there are more than 150 kinds of known manganese minerals, but there are only 5-6 kinds of manganese minerals which are high in manganese and can be enriched to form economically valuable manganese minerals. Among them, pyrolusite and psilomelane are of economic value. In addition, there are manganite, braunite, hausmannite, rhodochrosite, etc.

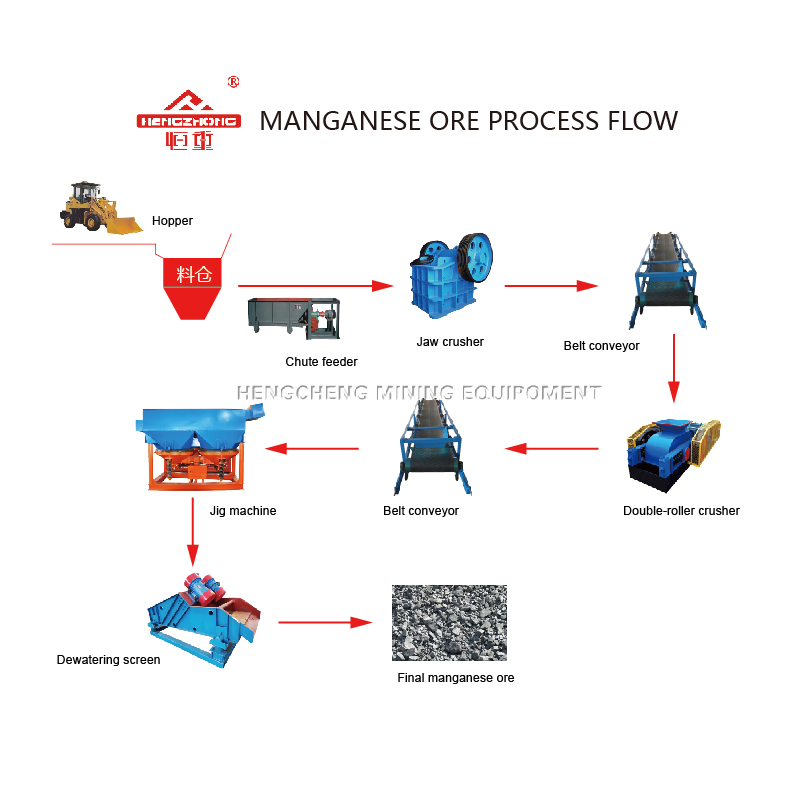

Most primary manganese ores cannot be directly used in smelting because its manganese content does not meet the industrial standard, so they must be beneficiated and purified before entering the industrial production. Manganese ore is mainly divided into manganese oxide and manganese carbonate, and its beneficiation methods include strong magnetic separation, gravity separation, flotation, fire enrichment, etc. Because manganese oxide ore has the characteristics of simple structure, coarse dissemination grain size and large density, the gravity separation method is usually used as the main ore processing, supplemented by strong magnetic separation,And jig machine is the main equipment used in the gravity separation of manganese oxide ore.

Jig machine can process coarse, medium and fine-grained manganese oxide ore, which has high separation efficiency and good separation effect, and is very suitable for large-scale manganese oxide beneficiation and purification. For this kind of coarse-grained manganese oxide ore, usually only crushing and screening are needed, the large manganese ore is crushed to mineral liberation degree, and then through screening, the ore within the range of the feeding size of the jig will be jigged, and finally get the coarse, medium and fine-grained manganese concentrate.

Jiangxi Hengcheng Minging Equipement specializes in the production of all kinds of mining equipment, mineral processing equipment, mineral washing equipment, etc. We offer high quality products, perfect one-stop solution service includes mineral process design, plant layout design, machine installation and debugging and so on, welcome customers to inquire.