Gravity Separation Equipment

Washing & Screening Equipment

Crushing & Grinding Equipment

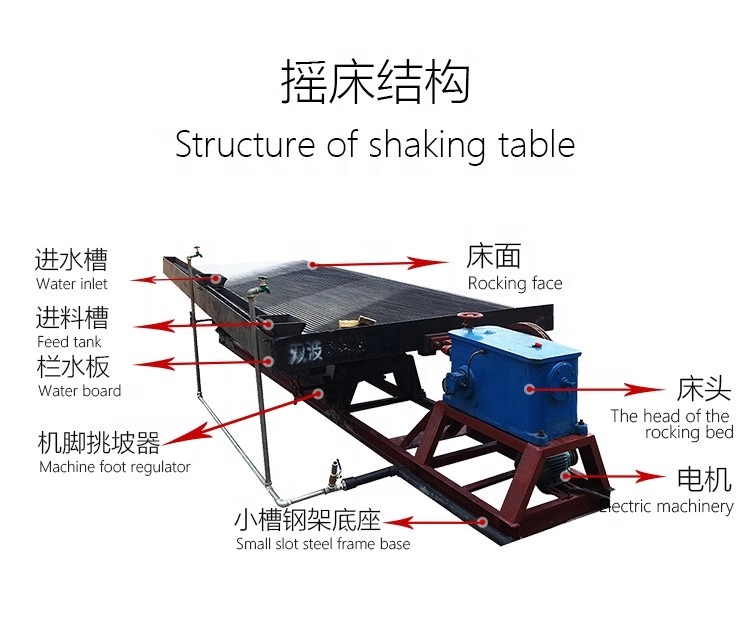

A gold shaker table, also known as a gold shaking table, is a specialized piece of equipment used in the gold mining industry to separate fine particles of gold from other minerals or materials. It is essentially a table with riffles or grooves on its surface that help to trap and concentrate the gold particles as they are shaken back and forth.

The working principle of a gold shaker table involves using the principles of gravity and fluid dynamics to separate gold particles from other materials. The table is set at a slight slope, usually between 2 and 5 degrees, and is shaken back and forth in a reciprocating motion. As the material to be separated is introduced onto the table, it is carried along by the flowing water and deposited onto the riffles.

The riffles on the table surface act as barriers to the flow of water and cause turbulence, which helps to concentrate the gold particles. The heavier gold particles settle into the grooves between the riffles, while the lighter material is carried away by the flowing water. The shaking motion of the table helps to keep the material in motion and prevent it from settling in one spot, which could cause the gold particles to be trapped in the lighter material.

1.High recovery ratio;

2.High concentration ratio;

3.Easy installation;

4.Simple operation;

5.Deck constructed of fiber glass;

6.Ten different decks to choose;

7.Long working life;

8.Adjustable stroke length and speed.

1. The gold shaker table will be delivered in 7 working days after receiving payment.

Our main products include Feeding Equipment, Crushing Equipment, Trommel Screen, Vibrating Screen, Ball Mill, Spiral Classifier, Shaking Table, Jig Machine, Spiral Chute, Centrifugal Gold Concentrator, Vibrating Sluice Box, Carpet Sluice Box, Gravity Separator, Flotation Separator, Magnetic Separator, Mixing Tank, Pump, Hydro cyclone, Sand Making& Washing Equipment, Laboratory Equipment.

We’d like to recommend a suitable model for you and send you a best quotation. So please give us some more information about your requirement in your enquiry.

1) What's the capacity per hour would you want ?

2) What 's the raw materials do you want to process?

Please swipe the phone to see the full parameters.

| Model | 6-S | |

| Deck Size | Length(mm) | 4500 |

| Transmission end width(mm) | 1850 | |

| Concentrate end width(mm) | 1560 | |

| Beneficiation area(m2) | 7.6 | |

| Feeding Size (mm) | Coarse sand Deck | 2-0.5 |

| Fine sand Deck | 0.5-0.1 | |

| Slime Deck | 0.1-0.037 | |

| Feeding amount (t/h) | Coarse sand Deck | 1-2 |

| Fine sand Deck | 0.5-1 | |

| Slime Deck | 0.3-0.5 | |

| Feeding Density (%) | 10-30 | |

| Water Added (t/h) | 0.5-3 | |

| Stroke (mm) | 8-36 | |

| Frequency (F) | 240-380 | |

| Transverse slope of Deck | 0°-5° | |

| Motor | Model | Y70L-4 |

| Power (kw) | 1.1 | |

| Weight (kg) | 900 | |