Gravity Separation Equipment

Washing & Screening Equipment

Crushing & Grinding Equipment

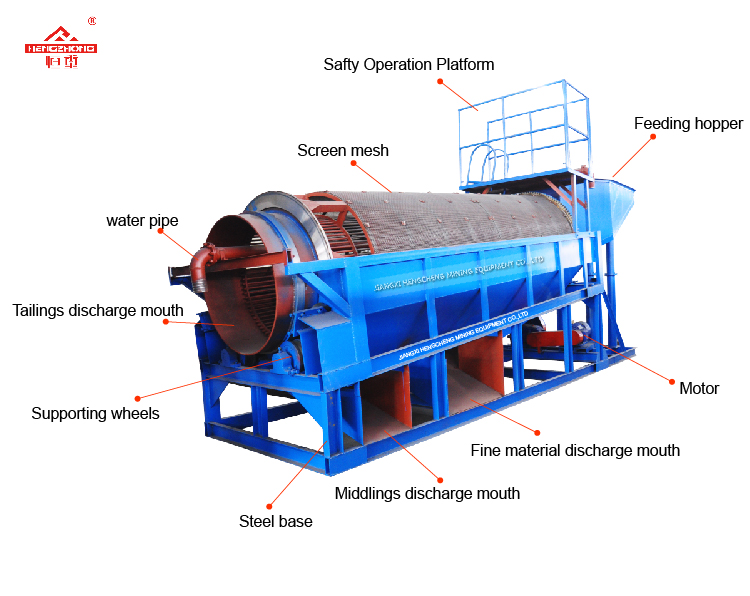

Trommel screen provides a simple, efficient and economical solution to upgrade a wide rang of material, and optimize the subsequent process steps of recovery. This method of screening helps not only to reduce manual operation and investment, also increase product grade, while allows rapid and large volume processing. Trommel screen is designed for processing alluvial gold mine, river placer sand gold, diamond etc.

Description

Trommel screen is usually used at the primary separation period of placer gold mining so as to washing and screening the gold ore. The upper sizes out are always reckoned as unuseful materials. The bottom sizes which contain the gold are usually processed by centrifugal concentrator or gold sluice box continuously to upgrade the gold ore. The concentrates of centrifugal concentrator could be processed by shaking table which is used to separate the gold from other minerals.

Working Principle

The raw material is put into the sieve cylinder through the feeding belt, and the rotating sieve cylinder drives the raw material to form the artificial sieve effect of the raw material sliding on the screen surface. Under the pushing and tumbling of the inner blade of the cylinder, the finished sand falls on the finished sand belt through the collecting hopper, and is lifted down by the belt into a finished material pile or directly into the storage hopper.

All of our gold mining trommels are able to be customized according to your requirement.

Main Features

1. Configured for economical & efficient classification, screening and grading.

2. Heavy duty trommel drum with lifters at the front to facilitate material break up.

3. Screen replaceable for different mesh sizes.

4. Multiple screen size.

5. Easily changed screen plates.

6. Largest processing capacity in the industry.

7. Unique screen design, result in higher capacities, longer screen life and no material clogging.

8. Heavy duty feed hopper and extension.

9. Discharge chute.

Our Trommel In Clients' Mine Sites

Packing and Delivery

1. All the goods will be delivered in 15-30 working days after receiving payment.

2. The machine will be packed in export container.

3. Motors and small parts will be packed in new strong wooden cases that suitable for long distance ocean transportation.

4. We promise that your goods will be shipped to destination timely and safely.

Our main products include Feeding Equipment, Crushing Equipment, Trommel Screen, Vibrating Screen, Ball Mill, Wet Gold Grinding Pan Mill, Spiral Classifier, Shaking Table, Mineral Jigger Machine, Spiral Chute, Centrifugal Gold Concentrator, Vibrating Sluice Box, Carpet Sluice Box, Gravity Separator, Flotation Separator, Magnetic Separator, Mixing Tank, Pump, Hydro cyclone, Sand Making& Washing Equipment, Laboratory Equipment.

We’d like to recommend a suitable model for you and send you a best quotation. So please give us some more information about your requirement in your enquiry.

1) What's the capacity per hour would you want ?

2) What 's the raw materials do you want to process?

| Model | Capacity (t/h) | Power (kw) | Drum Diameter (mm) | Drum Length (mm) | sieve mesh Size (mm) | Dimension (mm) | Weight (kg) |

| GT0510 | 1-5 | 1.5 | 500 | 1000 | <3~10 | 1800*1020*1500 | 1000 |

| GT1015 | 5-20 | 4 | 1000 | 1500 | <3~10 | 3000*1400*2145 | 2200 |

| GT1020 | 10-40 | 5 | 1000 | 2000 | <3~10 | 3460*1400*2145 | 2800 |

| GT1225 | 20-60 | 7.5 | 1200 | 2500 | <3~10 | 4146*1600*2680 | 4200 |

| GT1530 | 30-90 | 11 | 1200 | 3000 | <3~10 | 4460*1900*2820 | 5100 |

| GT1545 | 50-120 | 15 | 1500 | 4500 | <3~10 | 5960*1900*3080 | 6000 |

| GT1848 | 80-200 | 22 | 1800 | 4800 | <3~10 | 6500*2300*4000 | 7500 |

| GT2055 | 120-250 | 30 | 2000 | 5500 | <3~10 | 7500*2500*4000 | 8600 |