Gravity Separation Equipment

Washing & Screening Equipment

Crushing & Grinding Equipment

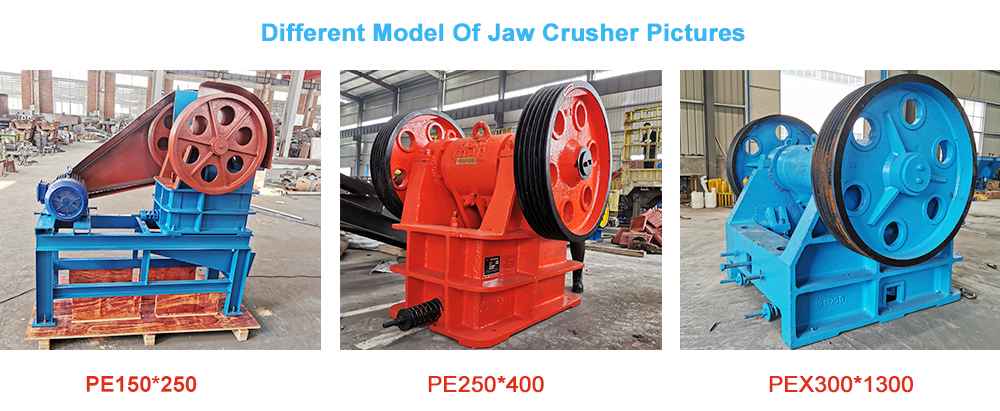

Jaw crusher is mainly used to crush kinds of mining stones primarily, and the largest compression resistance of the material is 320MPa. The jaw crusher is widely used in stone mining, metallurgy industry, building material, highway, railway, and chemical industry.

1. The deep crushing cavity increases the feeding capacity and output capacity.

2. High ratio of crushing, homogeneous final product size.

3. Adjusting the discharge opening through gasket, more convenient, it could meet different customers’ requirements.

4. Lubricate system is safe and reliable, easy to change the spare parts.

5. Simple structure, easy maintenance, energy consumption is lower.

6. Lower noise and dust.

Firstly the machine’s V-belt and wheel are driven by the electric motor, then the movable jaw plate begins to move up and down by the eccentric shaft, when the movable jaw plate moves from top to bottom, the angle between fixed jaw plate and movable jaw plate becomes smaller, the material is crushed into pieces to reach the crushing target. When the movable jaw plate moves from bottom to top, the angle between fixed jaw plate and movable jaw plate becomes bigger, the movable jaw plate deviates from the fixed jaw plate under the function of drag rod and spring, at this moment, the crushed material is discharged from the bottom outlet of the crushing cavity.

We’d like to recommend a suitable model for you and send you a best quotation. So please give us some more information about your requirement in your enquiry.

1) What's the capacity per hour would you want ?

2) What 's the raw materials do you want to process?

| Model | Feed Opening Size (mm) | Max. Feeding Size (mm) | Discharge Opening (mm) | Capacity (t/h) | Motor Power (KW) | Dimensions (L× W× H) | Weight (without motor) |

| PE150*250 | 150*250 | 125 | 10-40 | 1-3 | 5.5 | 875*845*935 | 1.1 |

| PE250*400 | 250*400 | 210 | 20-60 | 3-13 | 15 | 1500*1400*900 | 2.8 |

| PE400*600 | 400*600 | 340 | 40-100 | 15-40 | 30 | 1700*1800*1600 | 5.7 |

| PE500*750 | 500*750 | 425 | 50-100 | 20-70 | 55 | 1890*1940*1870 | 10 |

| PE600*900 | 600*900 | 520 | 65-130 | 50-150 | 75 | 2395*1843*2230 | 15.5 |

| PE750*1060 | 750*1060 | 630 | 80-140 | 72-130 | 110 | 2450*2466*2770 | 28 |

| PE800*1000 | 800*1000 | 700 | 80-140 | 80-220 | 75 | 2405*1850*2230 | 16.3 |

| PE900*1200 | 900*1200 | 860 | 230-290 | 200-250 | 132 | 3400*3200*3500 | 31 |

| PE1200*1500 | 1000*1200 | 1100 | 350-360 | 250-400 | 160 | 3800*3166*3045 | 51 |

| PEX150*750 | 150*750 | 120 | 10-40 | 3-13 | 15 | 1280*1610*1081 | 3.35 |

| PEX250*750 | 250*750 | 210 | 25-60 | 8-30 | 22 | 1400*1300*1350 | 4.9 |

| PEX250*1000 | 250*1000 | 210 | 25-60 | 10-40 | 30-37 | 1600*2000*1500 | 6.5 |

| PEX250*1200 | 250*1200 | 210 | 25-60 | 15-50 | 37 | 1900*2000*1500 | 7.7 |

| PEX300*1300 | 300*1300 | 260 | 25-90 | 20-70 | 75 | 1800*2300*1700 | 8.1 |