Product Details

Description:

An electrostatic separator works on the principle of exploiting the difference in the electrical charges of particles to achieve separation. When particles are introduced into the separator, they are given an electric charge using mechanisms like corona discharge or triboelectric charging. These charged particles are then subjected to an electric field, which exerts forces on them based on their charges.

Main Features:

1. The separator has a well-defined electric field region where the charged particles experience forces based on their charge-to-mass ratio. Positively and negatively charged particles will be attracted to regions of opposite polarity in the electric field.

2. The charged particles move within the electric field and experience both electrostatic attraction and repulsion forces. This leads to the deflection of particles with differing charges in different directions, allowing for their separation.

3. Once separated, the particles are collected in different bins or compartments based on their deflection trajectories. This collection can be manual or automated, depending on the setup.

Product Parameters

| Model | 4rollers | 2rollers |

|---|---|---|

| Number of rollers | 4 | 2 |

| Capacity | 800-2000kg/h | |

| Feed size | 20-80Mesh | |

| Rotating motor | each roller with 1.1 kw motor | |

| Material heater | (High Temperature)22kw | (High Temperature)12kw |

| Mineral divide drum heater | 1kw | |

| DC high voltage generator | 60kv/50mA | |

| Power supply | 3phases4wires | |

| Whole Machine Power | 16.5kw | 7.5kw |

| Machine(Excluding Motor) | 2250*1700*2170 | 1900*1140*2800 |

| Approx Weight | 2800Kg | 1500kg |

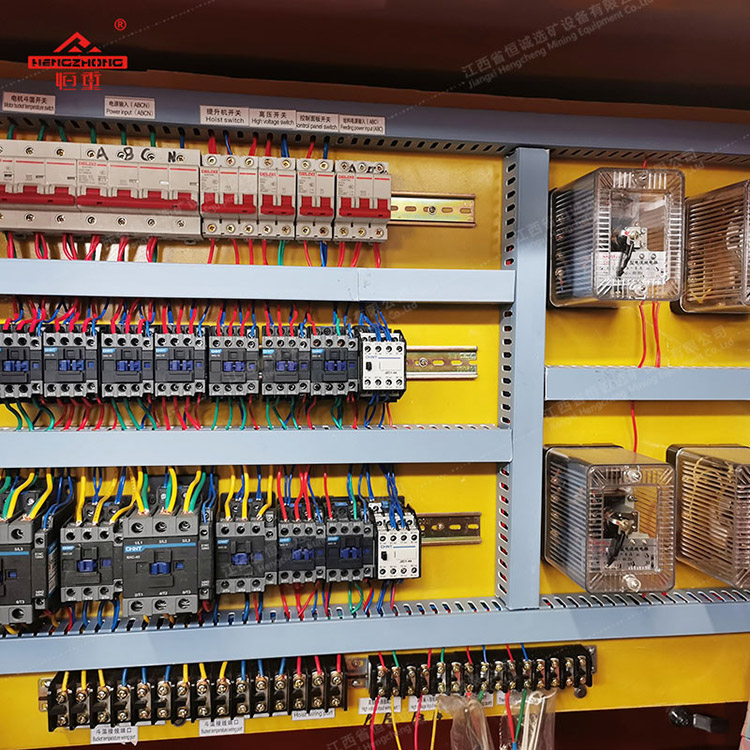

| Electrical Panel Cabinet Size | 800*450*1300 | |

| Bin size | 1900*1500*1100 | |

| Total height after assembly | 3180 mm | |