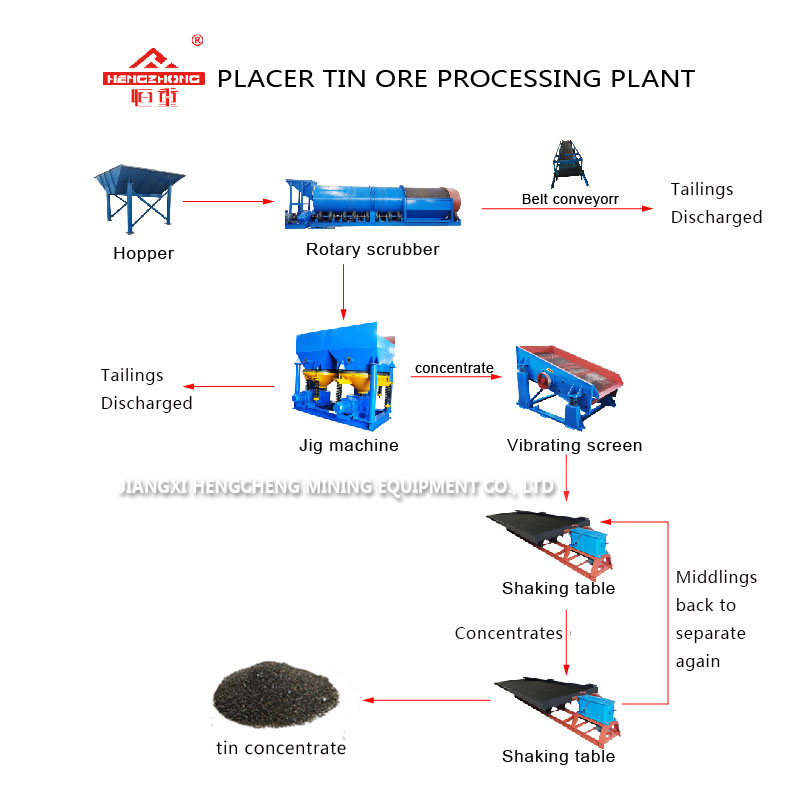

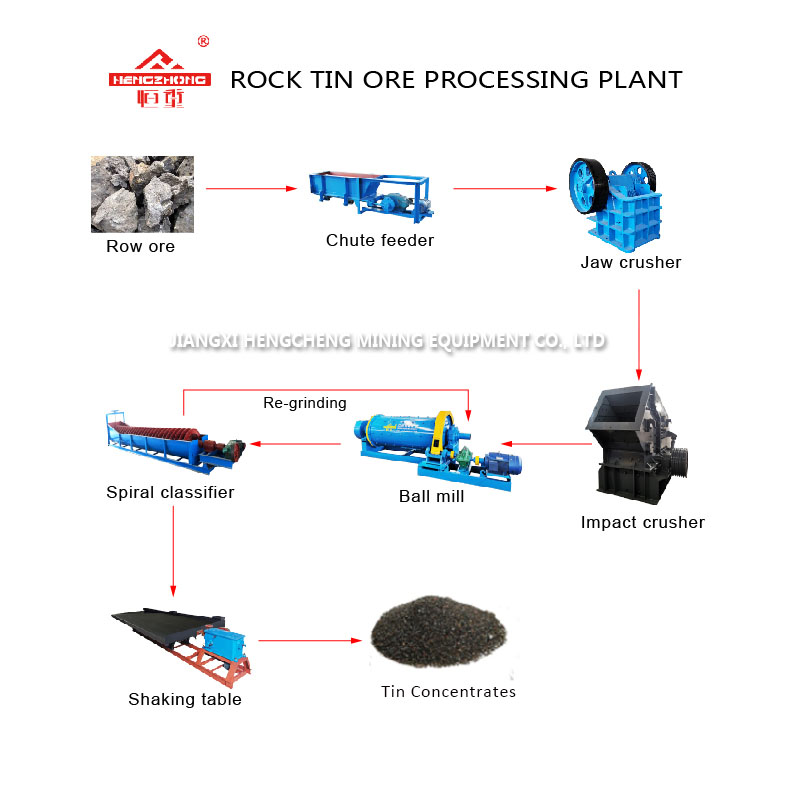

Tin ore is mainly divided into two types: placer tin ore and rock tin ore. Placer tin ore is found in riverbeds and alluvial deposits, is usually processed through gravity separation due to its high density. Rock tin ore, primarily composed of cassiterite (SnO₂), is embedded in hard rock and requires crushing, grinding, and further beneficiation methods such as flotation and magnetic separation. Efficient processing technology ensures high recovery rates and cost-effective tin extraction.

Above tin ore processing plant design, suited for the alluvial type and rock type tin ore, and those machines could effectively upgrade tin ore to 60% above.

Previous mining case working videos

Main Machines Pictures

Main Machine List For Tin Ore Mining

Placer Tin Ore Rock Tin ore

1 Rotary Scrubber 1 Chute Feeder

2 Vibrating Screen 2 Crushers

3 Jig Machine 3 Ball Mill+ Spiral Classifier

4 Shaking tables 4 Shaking tables

5 Water Pump 5 Water Pump

6 Belt conveyor 6 Belt conveyor

We’re not only tin ore processing plant supplier:

In addition to tin ore mining equipment, our company also has rich experience in other mineral ore processing, such as rock gold, placer gold, rutile, ilmenite, chromite, tantalum-niobium, diamond, copper, iron, tungsten, manganese, monazite, etc.

What we could do for every customer is one-package service:

Except for manufacturing the mining equipment, we also can provide:

◆ Engineering consultation,

◆ mineral processing experiments,

◆ Process Flowchart design,

◆ Installation and commissioning, Staff training,

All of our equipment can be customized according to your requirements.