Titanium iron ore (primarily ilmenite, FeTiO₃) is a critical raw material for titanium dioxide (TiO₂) production and titanium metal, widely used in pigments, aerospace, and welding electrodes. However, ilmenite often occurs with gangue minerals like magnetite, hematite, and silicates, requiring efficient beneficiation to achieve industrial-grade concentrates (TiO₂ >45%).

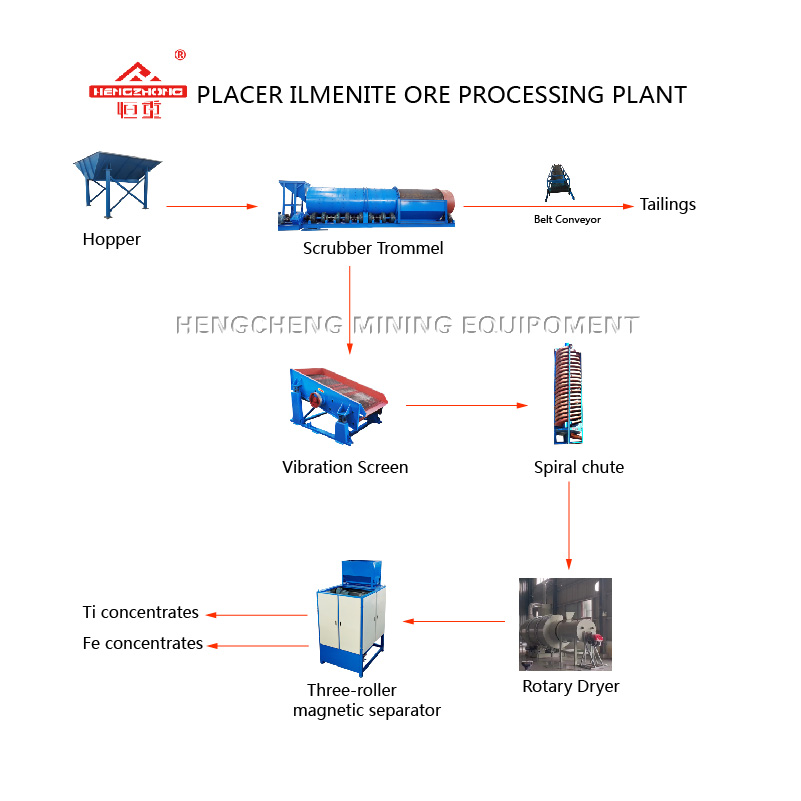

Different types of ilmentie ore process flowcharts

Our integrated processing plant combines crushing, gravity separation, and magnetic separation TiO₂ recovery while minimizing energy and water consumption.

From coarse ore to premium concentrate, we deliver turnkey plants with 85–92% recovery rates. Contact us to tailor a solution for your deposit!

Previous mining case working videos

Main Machines Pictures:

Main Machine List For Ilmenite Ore Mining

Placer Ilmenite Ore

1 Rotary Scrubber

2 Vibrating Screen

3 Spiral chutes

4 Rotary Dryer

5 Three roller magnetic separator

Rock Ilmenite ore

1 Chute Feeder

2 Crushers

3 Ball Mill+ Spiral Classifier

4 Spiral chutes

5 Rotary Dryer

6 Three roller magnetic separator

We’re not only ilmenite ore processing plant supplier:

In addition to ilmenite ore mining equipment, our company also has rich experience in other mineral ore processing, such as rock gold, placer gold, rutile, tin , chromite, tantalum-niobium, diamond, copper, iron, tungsten, manganese, monazite, etc.

What we could do for every customer is one-package service:

Except for manufacturing the mining equipment, we also can provide:

Engineering consultation,

mineral processing experiments,

Process Flowchart design,

Installation and commissioning, Staff training,

All of our equipment can be customized according to your requirements.